Chriske

-

Posts

1,421 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Gallery

Events

Blogs

Posts posted by Chriske

-

-

I'm a bit surprised you did not print a focuser...

-

I think you should try a combination of wood and this focuser.

I used printed wheels and O-rings to do the friction on that printed eyepiece-barrel.

If you have no lathe, printers or other machines at your disposal you could make the main body out of wood. The rubber wheels, you can cannibalise them from old copier(zerox) or printers.

You also could make a Crayford. The ball bearings can be replaced by small, thin strips of teflon.

In both cases you could use a PVC pipe as eyepiece-barrel.So many possibilities, I'd ask Mr Google, just type 'Wooden focusers' or 'Homemade focusers'. Tons of homemade stuff.

-

12 minutes ago, AlentejoSkies said:

.ipt files will be very okay. Thank you!

Beside the printed parts you need a aluminium barrel. It has no plane, there's no need to. The diameter of the barrel needs to be precise.

Also a few 6x10x2.5mm ball bearings, and an axis that fits inside the bell bearings.

If you do not use the dual speed device, you need to redraw just a little bit. The big hole on the right side must be made smaller to allow a ball bearing That big hole on the right side is in fact to make room for that dual speed device. Pressure on the alu barrel is done with a very small bolt at the left(front) -

3 minutes ago, CraigT82 said:

I really need to get myself a 3D printer!

Your life will never be the same again...😁

-

2 minutes ago, CraigT82 said:

I really need to get myself a 3D printer!

Just do it...!!!😁

-

ipt files OK..?(Autodesk Inventor)

-

I'm busy doing exactly the same, together with my son.

Also a Darkstar 12" f/6.

Think we're going to dump the tube and the(to) heavy Dob and make a truss instead.-

2

2

-

-

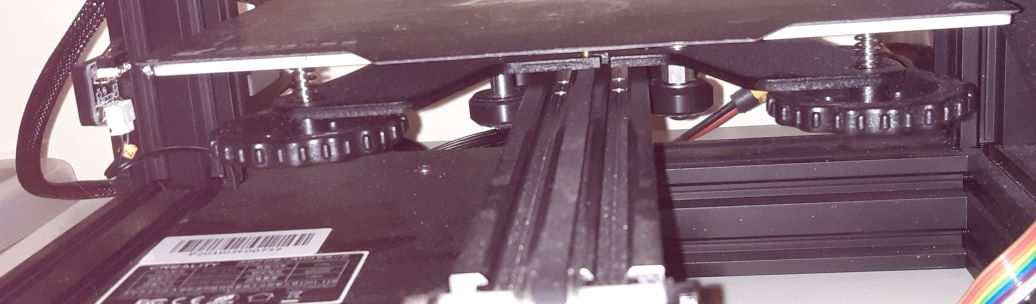

Of course there's a gap now.

After tensioning the springs you need to adjust the Z-homing screw.4 hours ago, Thalestris24 said:Ok, I tried tightening up all four nuts. However, that leaves the nozzle about 8mm above the bed... The vertical home position of the nozzle is fixed by the position of the microswitch. I can't see any way to move that up so I'm pretty much back to square one. Looks like the only way to get the right height is to loosen the springs again.

Louise

-

1

1

-

-

10 hours ago, Thalestris24 said:

Maybe the springs are not strong enough for the task.

You might try this :

Tighten all screws to close the springs completely - do not overdo-. 'Relax' the springs by turning all knobs one revolution(loosening). Now you have maximum force on the bed.

Then level the bed again by only loosening the knobs. -

11 hours ago, johninderby said:

I adjusted the bed a couple of years ago when I got my printer and haven’t had to adjust it since. And it has been moved a few times.

Me too..

My beds are spring-loaded at four corners. -

Meanwhile all external HST's parts, that needs to be printed, are drawn. Most of them by Michel, he just started learning 3D drawing btw. He becomes rather good at it.

One of these days, when weather allows it, I'll start building HST's outer perimeters.The hardboard panels needs to be soaking wet to bend over a plastic(or other) tube.

-

Frustrated...? How so..?

-

1 minute ago, andrew s said:

... extracting the faintest wisp via image processing and freezing ones *** off to arm chair warmth.

Regards Andrew

That's what he's planning to do with that 300mm 'beast'. Astrophotography..!

We need to make a very sturdy mount for that thing.

He'll probably be using a Box-mount.-

1

1

-

-

As a matter of fact, my son just started grinding his own optics.

So that makes him old fashion too...?😁

Just kidding, I'm very glad he did, he's almost 40...-

1

1

-

1

1

-

-

I do have very good ear buds btw...BOSE...😁

-

1

1

-

-

So Andrew, I'm just been nostalgic or old fashion...??😉

-

Well about these questions...

A few days ago I was busy restoring (and recovering optics out of) a few telescopes.

Reason :

Got a phone-call from another member of our local observatory. He told me been busy cleaning/making room in one of our lumber rooms.

His plan was to dump a few telescopes(literal : throwing away)

One of these scopes was a 300mm Dob. It is a very good scope. Bought in the '80 from DarkStar (UK)

Another four 250 mm Dobs aren't used anymore. One 200mm + a few other smaller scopes. Amongst them a 70mm Maksutov.Mind-boggling decision not..?..😳

Asking questions our manager told me that our youngsters don't seem to enjoy observing anymore. Lots of these younger members are 'stuck' behind their laptop he added.40 years ago a 300mm telescope, to us it was a un-reachable goal..! Way to expensive in those days..!

-

1

1

-

3

3

-

-

Are our youngsters less interested using real telescopes these days...?

...or is there a new generation 'laptop amateur astronomers' in the making..?I need to explain a thing or two about these questions, but I wonder how many youngsters are still at it, not just building, but also observing the night sky.

-

One of the 'parts' hanging around HST is this little guy. Not top quality, but that has all to do with the speed I'm printing(100+mm/s)

Need to paint the helmet 'glossy-gold'.

Actually there will be a few of these 'astronauts' holding on to the metal handles.

I wonder, do they always grab the handles to 'float' from one point to another or are they secured by a 'rope'..?I might add a cordless drill or a hammer to put in their hands(or a hacksaw...😁)

-

3

3

-

-

Awesome project..!!

I'm drooling here...

-

1

1

-

-

The manager of our observatory asked me to make an even bigger SaturnV rocket.

This next (last?) one will be 3.6meter high, Crawler and launching platform included.

Adding the umbilical tower on the launching platform the complete structure will be almost 4 meter high.

For this job I need to build a bigger printer first.

Deadline mid-Sept 2020.Some smaller parts I'm already printing now, like the Caterpillar shoes for the Crawler. I need about 450(!) of these.

-

4

4

-

-

-

Meanwhile another member of our observatory (Michel) joined me drawing HST parts. I'm very happy with him helping me of course.

We already did lots of preliminary drawing.-

1

1

-

-

Nice looking indeed and nicely done too..

But there are far simpler startrackers that can be printed.

Two printed arms, a hinge, a threaded rod and a stepper. That hinge is the polar axis.-

2

2

-

Printed Focusers.

in DIY Astronomer

Posted

While doing a surge on the net I found this one.

I made it many many years ago, I completely forgot about it...

Teflon strips to guide the focuser barrel. And If you look closely, around the focusing rod is a very thin shim of teflon too.