-

Posts

434 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Gallery

Events

Blogs

Posts posted by Herra Kuulapaa

-

-

The weather has been exceptionally bad here. I was out yesterday evening and waited three hours for clouds to clear but it never happened. Despite of the constant roll of thick clouds I was able to get single ISO800 / 110 sec HA frame during one brief opening. Other holes lasted only 30 sec so they were practically useless. Ground is covered in snow however, so it will be a white Christmas!

Due to the limited exposure I had to stretch the frame rather hard. It serves as a proof of concept for the D5100 Mono-HA project though.

-

3

3

-

-

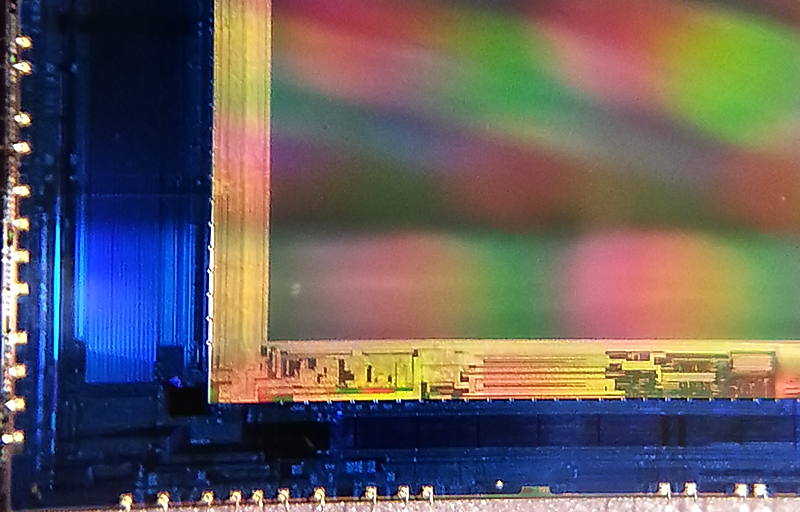

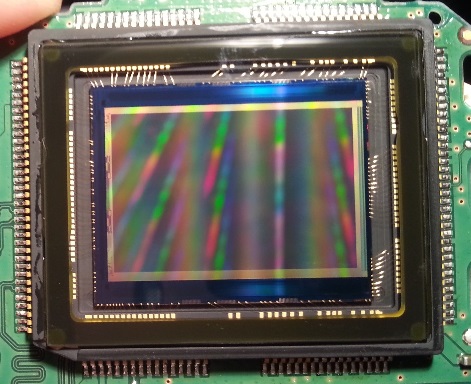

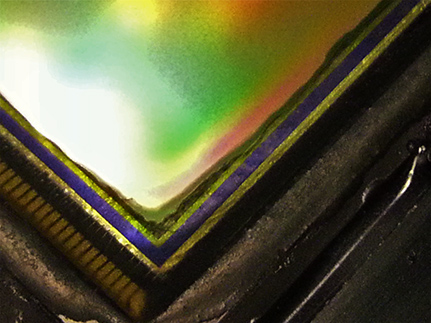

Some microscopy images. There are so many "do not touch"-structures existing.

The almost invisible gold wires:

The blue areas:

The golden lining:

-

3

3

-

-

average...

-

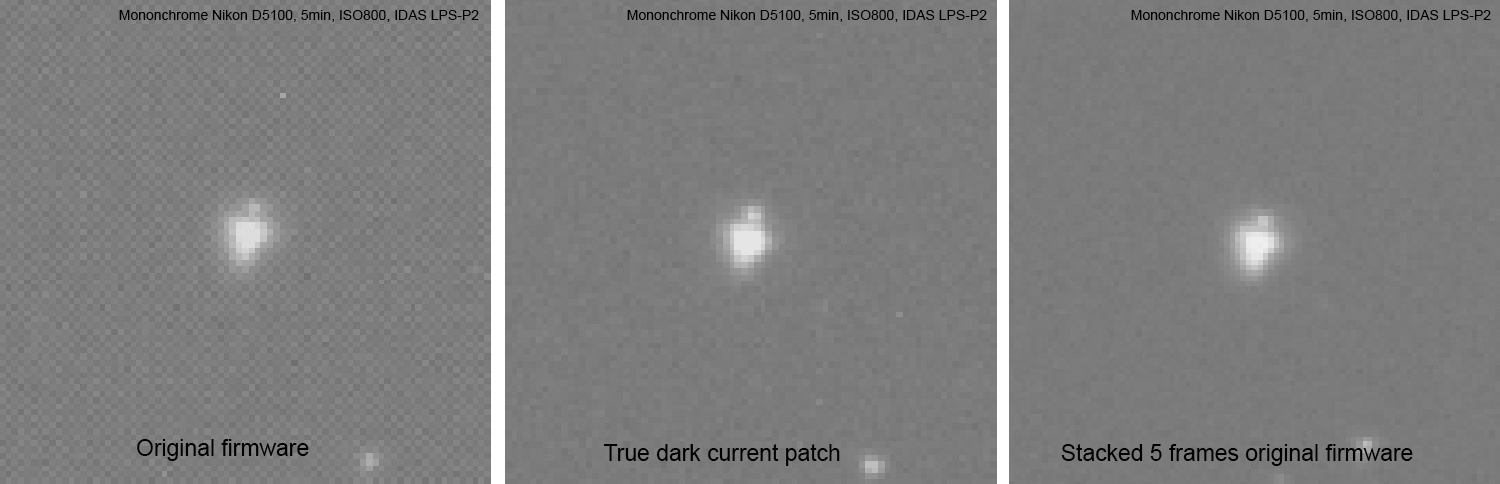

Small comparison about the pixel grid and how it behaves when stacked. 5 frames seem to be enough to avarage it out.

-

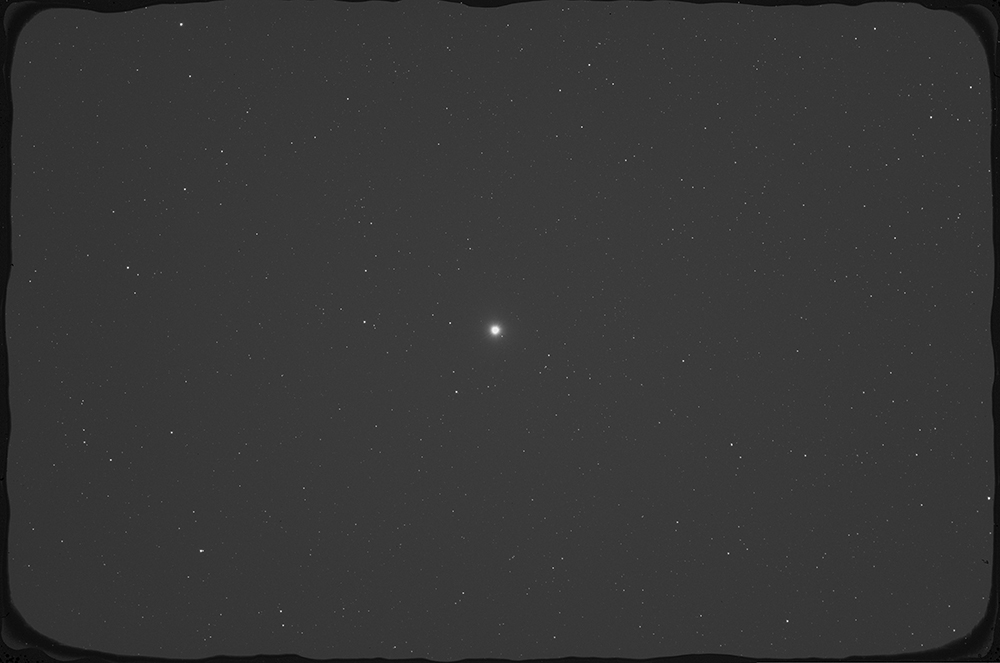

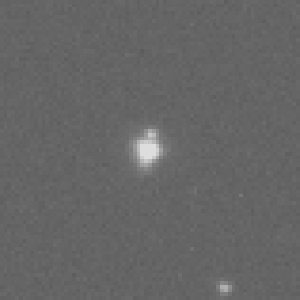

One sample frame with some dust on it:

This was taken under relatively bad sky with IDAS LPS 5min ISO800 D5100.

-

4

4

-

-

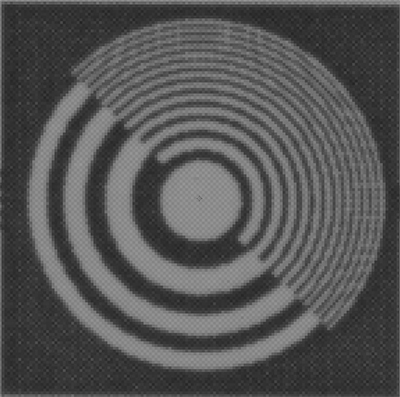

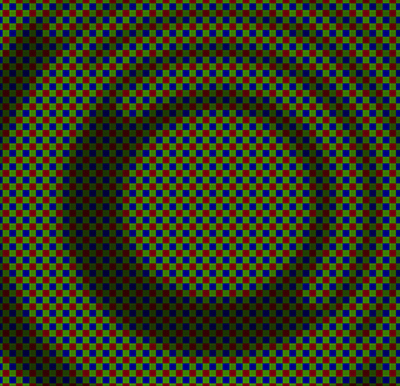

I have been struggling with that checkerboard pattern with my Nikon D5100. So far I've thought it to be some kind of filter remains but today I made an interesting discovery.

This is what I've been seeing in every file:

But with Nikon hacker true dark current mod the pattern is gone:

This is very good news for D5100!

-

2

2

-

-

Here is a small report of my D5100 project.

http://kuulapaa.com/home/astrophotography/nikond5100mod.html

Ps. Some people may find the other material on the page interesting as well.

-

2

2

-

-

Interesting, thanks J

You seem to suffer from extensive IR exposure (blob stars). Do you have a naked sensor?

-

Small break due to heavy workload, but back again.

There seems to be remains of RGB matrix still on sensor. This layer is really hard in Nikon D5100.

-

Sensors are different and so are the resins between glass and sensor frame. I've noticed a trend of harder and more heat resistant resins when moving towards most recent models in Nikon line up. Glass bond is much more heat resistant.

I discussed with one chip engineer and he suspected that despite and because of good thermal conductivity of silicon the sensor internal temperature may not rise too high even during relatively heavy local heating. As long as the whole sensor is not baked in oven.

I'm currently fighting one chip with heat trying to guess how far I can go. And therefore, does anyone have info how much heat sensors can actually take?

-

Based on my experience I'd say those sensor sides are strictly off limits. Lots of delicate wiring packed in very small space and probably built not to be scratch proof.

One mistake there and you'll end up making modern art of your astro images. Really fascinating though...

-

1

1

-

-

Won't it look like that anyway if you are telling PI to create an RGB image?

I would have thought you would need to image something distinctly red, green or blue and check all the pixels expose.

I wasn't very clear in my previous post. You're right, only monochrome is right way to look image.

I blame a bit late evening

-

Won't it look like that anyway if you are telling PI to create an RGB image?

I would have thought you would need to image something distinctly red, green or blue and check all the pixels expose.

I believe color is just something how software interprets sensor data. Well, obviously it is, but you know I mean debayered vs non-debayered image

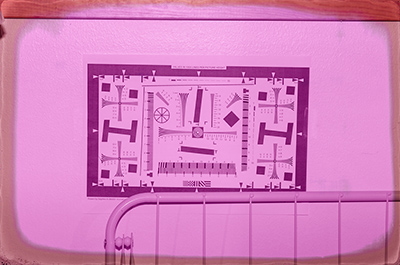

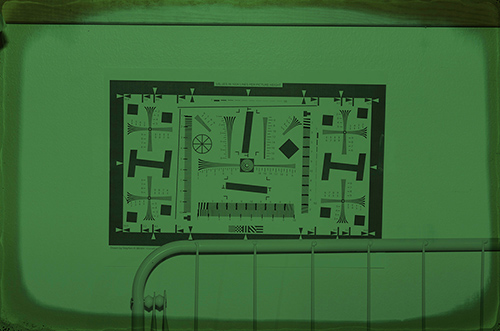

Same file opened in Photoshop gives that distinctly red image, but the presence of RGB filter can be only seen indirectly by color channel distribution:

Pixinsight means by RGB image that non-debayered image format has color pixels, if such is existing (?).

To verify this: Same picture presented as monochrome shows checkerboard pattern so RGB filter is there.

-

Images above are Pixinsight raw data extracts with settings:

-

This is a first test of in process Nikon D5100 sensor.

I haven't processed the edges yet and it seems that although micro lenses are off, the color filter still remains. RAW green channel is clearly more dominant than red or blue.

Here is also the raw file:

http://kuulapaa.com/Tahtidata/debayer.NEF

Do you agree?

-

Forgot the picture:

-

My observations on Nikon D3100 and D5100 sensors.

These two sensors are clearly different from each other. D3100 felt like walk in a park with flat sensor/cover glass surface. Glue wasn’t too strong and glass felt thicker and even flexible. In other words it came off rather nicely.

D5100 however is a completely different case. Thinner? cover glass was is not glued on flat surface but it’s instead embedded in groove 1/3 deep of the glass height – so it’s very hard to get under the glass. Also the gap between sensor groove and cover glass was partly filled with resin. Only one corner is left open and if you mess it up, then rest of the process is much harder. Also the resin seems to be much stronger and heat resisting than in D3100. Gold wires, they are rather short in D3100 and only located on two sides, but the D5100 has long wires covering all four sides of the sensor. Combined with shattering glass the higher gold wire damage risk makes D5100 sensor not so desirable debayering sample. Persons with certain personality characteristics may enjoy it though

I’d guess that as D5100 sensor is made by Sony, they have different manufacturing process than Canon or Nikon. [i recall reading that D3100 is Nikon made and D5100 Sony. Please correct me if I’m wrong.]

-

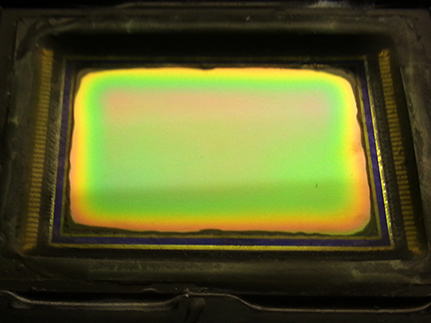

The Nikon D3100 sensor is almost ready but I'm wondering one thing of it.

That reddish/orange color can be seen on the sides but otherwise the whole sensor is greenish. (that different tone area inside green tone is just a lamp reflection).

I have worked the green area quite much but still it doesn't change. Should I keep going on the green, what do you think?

It's dirty I know, still in process...

-

I did some tests with slow, semi fast and fast curing household epoxy resins and conclusion seems clear.

Faster the resin, more shrinkage and heat the curing causes (at least with tested substances).

Slow curing Araldite was least shrinking although some minor shrinkage was visible. There war clear shrinkage with Araldite rapid. I’d estimate that because of the low magnitude of shrinkage the slow curing Araldite should be ok and not tear any gold wires off the sensor when curing.

Method was to fill up straight wall .22 long rifle cartridge casing with resin, even the resin amount to casing and observe how much resin surface was lowered during curing.

-

I have one Nikon D5100 body lying around and the plan is to convert it monochrome ie removing bayer matrix.

Before actually starting do it I’d like to ask if anyone has experience on this specific sensor model (also D7000 sensor) and are there any special advices for it?

I read the whole thread through, relatively fast though and noticed that one shouldn’t go too close the edges because of some invisible wiring or something. Most of the examples were however Canon sensors so I’m wondering how this applies to Nikon ones?

Reference picture:

Debayering a DSLR's Bayer matrix.

in DIY Astronomer

Posted

Hmmm, my D5100 project seems to be finished now and I just need to start using it. One observation about the sensor is that it's rather easy to make surface very uniform compared to Canon xxxD series.

Here are two examples of the D5100 monochrome. Both images are stacks of 4x600s / ISO800 through 12nm hydrogen alpha filter.

Or should I make active cooling to it?

http://kuulapaa.com/index.html